The Critical Role of Dry Ice in the Pharmaceutical Industry

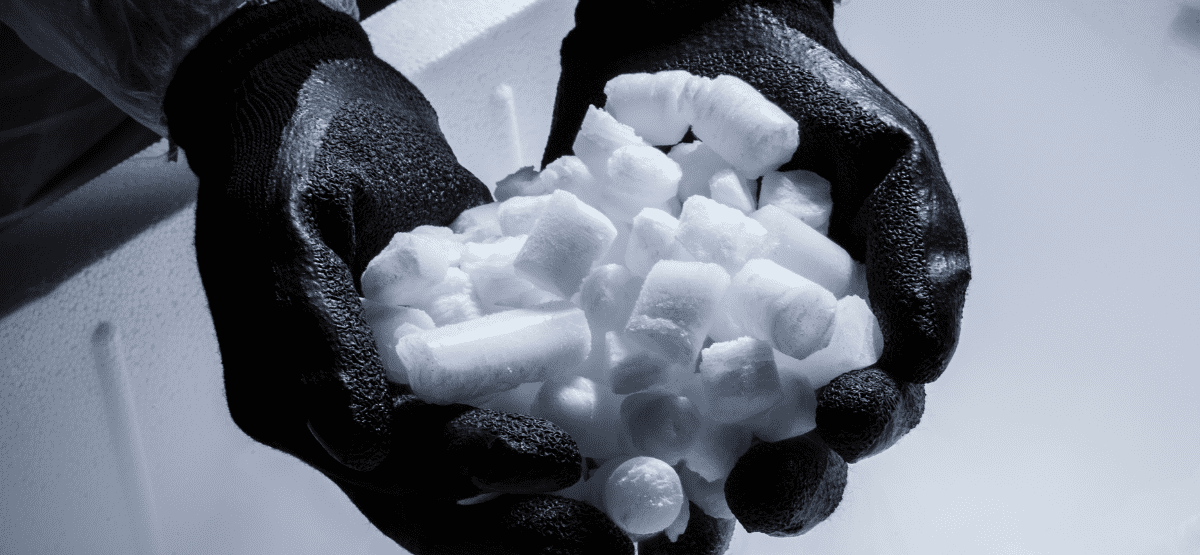

Dry ice plays an indispensable role in the pharmaceutical industry, serving as a crucial component in cold chain management, especially for drugs requiring ultra-low temperature storage. Its ability to maintain temperatures as low as -78.5°C makes it vital for preserving the effectiveness of biologics, vaccines, and other temperature-sensitive products.

Importance of Ultra-Low Temperature Storage

In the pharmaceutical sector, maintaining the precise temperature of products is mandatory to preserve their efficacy. Dry ice shipments ensure that pharmaceuticals remain within the critical temperature limits, which is essential for products that require consistent cooling. Utilizing dry ice in applications enhances the stability of sensitive drugs during transit and storage. For further details, visit The Role of Dry Ice in the Pharmaceutical Industry by nexAir.

Applications in Clinical Trials

Clinical trials benefit significantly from dry ice, as it ensures biological samples preservation and meets both scientific and regulatory standards. Proper logistics and handling techniques are pivotal to maintaining the viability of these samples. Explore more in Dry Ice in Clinical Trials by Medicover Integrated Clinical Services.

Enhancing Vaccine Transportation

With recent global health challenges, the need for efficient vaccine distribution has been heightened. Dry ice is a fundamental component for medical and pharmaceutical cooling, ensuring that temperature-sensitive products, such as vaccines, reach their destination without degradation. Learn how dry ice plays a role in shipments at Dry Ice for Medical & Pharmaceutical Shipments.

Best Practices in Pharmaceutical Dry Ice Usage

Implementing best practices in the use of dry ice can ensure pharmaceutical products are transported efficiently and safely:

- Proper Insulation: Use high-grade insulated containers.

- Strategic Packing: Position dry ice to ensure uniform cooling.

- Monitoring Systems: Use temperature tracking to comply with regulatory standards.

- Regulatory Standards Compliance: Adhering to guidelines is crucial in maintaining drug safety. For more about pharmaceutical applications, see The Benefits of Dry Ice in the Pharmaceutical Industry.

Overcoming Super Cooling Challenges

Super cooling presents a significant hurdle in the pharmaceutical cold chain. Dry ice applications must be optimized to overcome these challenges effectively. Discover solutions in Solving Super Cooling in Pharmaceutical Dry Ice Shippers.

Future Prospects in Cold Chain Management

As the industry advances, sustainable approaches and innovations are becoming increasingly important. Strategies such as eco-friendly dry ice production and reusable packaging are pushing the boundaries of what is possible. By implementing these strategies, pharmaceutical companies can work towards a more sustainable future without sacrificing safety and quality.

FAQs

What are the main applications of dry ice in the pharmaceutical industry?

Dry ice is used in temperature-sensitive drug shipments, clinical trial logistics, and medical materials transport. It helps in maintaining ultra-low temperatures necessary for preserving drug efficacy.

How does dry ice improve vaccine distribution?

Dry ice ensures that vaccines travel through cold chain logistics without temperature fluctuations, crucial for maintaining their integrity.

What are the regulatory considerations when using dry ice?

Temperature monitoring and regulatory standards compliance are essential to ensure pharmaceuticals remain effective throughout their lifecycle.