Industrial Chemical Packaging: Evolution and Outlook in a Changing Europe

In today’s fast-evolving industrial landscape, European chemical packaging is undergoing a significant transformation. Once seen merely as a means to contain chemicals safely, packaging has grown into a critical component of business strategy. The global shift is driven by stricter regulations, environmental mandates, and technological innovation. Across Europe—and indeed around the world—industry leaders are rethinking how they package products, integrating advanced materials with smart technology, and carving out new business models that reconcile safety, cost efficiency, and sustainability.

This opinion editorial aims to dive in to the current state and future projections of industrial chemical packaging. Alongside the perspective of industry trends as captured in recent press releases, we will also discuss related topics such as data consent and digital transparency in corporate operations. Throughout, I will carefully highlight the practical implications for businesses, government regulators, and supply chain professionals, while using everyday language to break down some of the tricky parts and tangled issues behind this evolution.

Digital Transparency and Data Consent: Balancing Privacy with Innovation

Before we dig into the heart of industrial packaging, it is important to address an entirely different—but increasingly interlinked—aspect of our interconnected world: digital privacy and data consent. Modern business operations, spanning everything from packaging innovation to marketing analytics, rely on digital data collection. Websites, for example, use cookies that collect various pieces of information about an end user’s device and behavior.

Consent to cookies and data processing policies, as detailed on many company websites, often support the integration of content, social media, personalized advertising, and even statistical analysis. While this might seem like a small matter, these data practices are tied to deeper issues of privacy compliance, legal oversight, and even potential exposure to off-shore scrutiny. As businesses integrate third-party services into their operations, data can end up being accessed by locations like the USA—where government access might occur without immediate legal recourse.

As a result, companies must find a way to manage their digital presence while safeguarding consumer data. By offering options such as “Accept All,” “Reject All,” or customized cookie settings, organizations allow their users to figure out a path that respects both convenience and confidentiality. This approach of direct consent not only builds trust but also lays the groundwork for more transparent digital interactions—a practice that complements the drive towards smart, transparent industrial processes.

Understanding European Packaging Trends: A Shift Toward Sustainability

Across Europe, a seismic shift is occurring in how chemicals are packaged, transported, and handled. Under increasing environmental pressure and regulatory mandates, companies in the chemical and petrochemical sectors are abandoning conventional packaging solutions. They are turning to sustainable, reusable, and high-performance systems that promise both durability and safety.

The renewed focus is on the careful selection of materials—from high-density plastics to specialized barrier coatings that combat chemical reactions and environmental degradation. The surge in sustainable demand means that packaging isn’t just a passive container; it is rapidly becoming an active component in reducing emissions and ensuring compliance with green standards. As industrial chemical packaging evolves, the industry is learning to manage its debt of responsibility toward environmental stewardship while continuing to offer secure, compliant containment solutions.

Material Innovation and the Rise of Sensor-Enabled Containers

At the heart of this evolution is the innovation in new materials. Companies are investing in developing plastics and composites that not only resist chemical reactions but also integrate smart technologies. These sensor-enabled containers are capable of real-time monitoring—detecting leakages, tracking temperature fluctuations, and even reporting on the integrity of a sealed system. As such, the hidden complexities of packaging have been reduced to a series of measurable factors that can be managed remotely, providing reassurance to regulators and end users alike.

By adopting these innovations, the industry makes a bold statement: the future of chemical packaging is intertwined with digital technology. Manufacturers are stepping up to the challenge of the overwhelming task of ensuring safety while boosting operational efficiency, and they are doing so by incorporating measurable, data-driven controls into the traditional processes of storage and transport.

Key Market Drivers: Navigating the Regulatory and Technological Landscape

Regulatory oversight is one of the primary drivers pushing the industry away from traditional packaging systems. Governments around the globe, and especially in Europe, have increased their scrutiny over chemical storage and transportation. New laws require UN-certified packaging and strict adherence to environmental standards. The shift has been spurred by the following factors:

- Environmental Regulations: Governments are mandating the use of eco-friendly containers that minimize waste and reduce carbon footprints.

- Safety Standards: Strict compliance measures require heightened vigilance in ensuring that chemical containers are resilient and capable of preventing leaks and spills.

- Cost Efficiency: Companies are incentivized to adopt packaging solutions that reduce long-term costs, even if the initial investment appears high.

- Technological Advancements: The integration of sensor technology and automation in packaging systems is rapidly becoming a super important competitive advantage.

This combination of factors is turning what once might have been seen as an intimidating set of challenges into opportunities for the industry to innovate and reinvent itself. The emphasis is no longer strictly on the cost of materials, but rather on the total system performance, including long-term sustainability and safety metrics.

Smart Packaging Technologies: Sensor Integration and Automated Systems

With the advent of digital monitoring, companies are now looking at smart systems to take the wheel in managing packaging operations. Sensor-integrated containers can detect small fluctuations in temperature, pressure, and chemical composition—these subtle details prove to be super important in preventing hazardous conditions during transit and storage:

- Real-Time Monitoring: Sensors offer a constant stream of data, allowing logistics teams to figure a path through potentially tricky operational challenges.

- Automated Safety Protocols: Automatic alerts and system checks contribute to faster responses when conditions begin to deteriorate.

- Enhanced Compliance: By aligning with stringent regulatory standards, sensor-based systems help companies maintain certification and avoid penalties.

As these smart technologies gain traction, they are set to revolutionize the practice of industrial packaging. While the adoption of such tech-driven solutions may initially appear nerve-racking, the benefits emerge gradually following careful, step-by-step implementation and testing.

Regional Perspectives: The Impact of Global Investment in Packaging Innovation

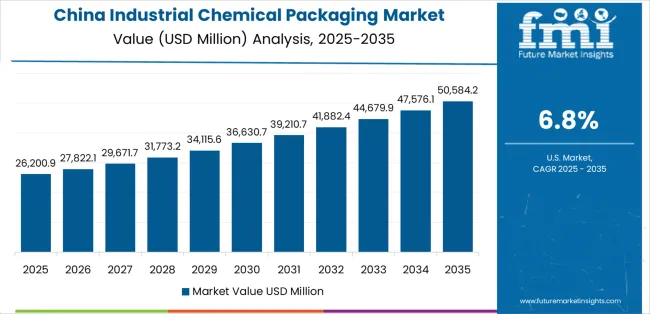

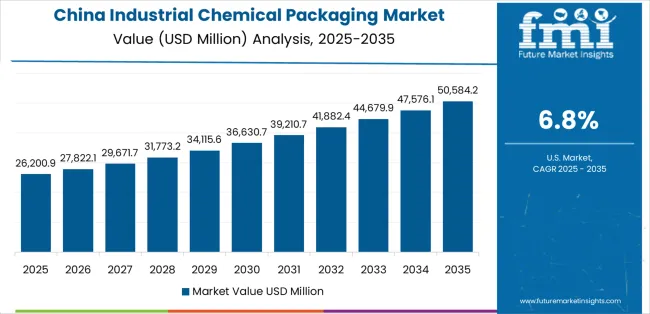

While Europe is a focal point for new packaging standards, the ripple effects of these changes are being felt worldwide. In regions like Asia-Pacific, where countries such as China and India are significantly expanding their petrochemical capacities, the demand for robust industrial packaging systems is exploding. These markets are investing heavily in new manufacturing processes that meet international safety and environmental standards.

In mature markets like North America and parts of Europe, companies are embracing high-performance packaging solutions as a response to increasing global trade and cross-border shipments. In these arenas, both the tangible benefits of reusability and the less-visible improvements in regulatory compliance are driving market growth.

As these distinct regions make headway, the overall market shows a steady annual growth—a clear testament to the increasing reliance on certified, advanced packaging solutions. In response, manufacturers are working through the planning and implementation stages required to satisfy both traditional requirements and the rising demands of modern, tech-savvy consumers.

Industry Leaders and the Competitive Landscape: Who’s Leading the Charge?

The competitive arena within the industrial chemical packaging market is as dynamic as it is competitive. Industry heavyweights such as Greif Inc., Mauser Packaging Solutions, Berry Global Inc., Sealed Air Corporation, and Sonoco Products Company command nearly half of the global market share. Their dominance stems from:

- Deep Technical Know-How: These firms have invested years in understanding the challenging bits of chemical containment technology, from material performance to compliance roadmaps.

- Global Distribution Networks: Their established networks ensure prompt and reliable delivery across global markets, crucial for maintaining supply chain integrity.

- Diverse Portfolios: A broad spectrum of UN-certified solutions helps them cater to varied consumer needs—from industrial-grade acids to sensitive solvents.

- Strategic Research and Development: Continuous R&D efforts focus on integrating smart technologies and enhancing material performance, ensuring that they remain ahead of industry trends.

While the market remains moderately fragmented, the competition is more about material innovation and compliance improvements rather than merely engaging in price wars. Each leading provider is investing in super important R&D initiatives and strategic partnerships that are aimed at perfecting their offerings. These partnerships not only bring technical expertise together but also facilitate the rapid deployment of smart packaging solutions that are aligned with international standards.

Sustainability and Automation: Laying the Foundation for 2035 and Beyond

Looking ahead to 2035, sustainability and automation emerge as the two central themes that will shape the future of industrial chemical packaging. The environmental landscape is undergoing a dramatic shift, with companies and governments alike committed to reducing waste and environmental impact. At the same time, automation is streamlining production lines and safety protocols, bringing about an era of seamless integration between physical and digital systems.

On the sustainability front, expect a surge in demand for containers made from recycled materials. Today’s companies are already testing, and in some cases deploying, packaging solutions that incorporate significant recycled plastic content and other renewable materials. By embracing a circular economy model, many industry leaders are offering take-back programs, ensuring that used containers are recycled and repurposed rather than ending up as waste. This approach not only reduces environmental strain but also aligns with stringent governmental green policies.

Automation, meanwhile, takes center stage as companies deploy smart systems for monitoring and control. The fusion of digital technology with robust physical packaging solutions is gradually reducing the nerve-wracking aspects of manual oversight. Automated, sensor-enabled systems are capable of:

- Detecting operational anomalies early, thereby minimizing the risk of accidents during transport.

- Streamlining regulatory compliance by automatically logging and archiving performance data.

- Reducing labor costs and enhancing efficiency in large-scale chemical handling operations.

The combination of sustainability and automation offers a promising path forward. Companies that successfully integrate these elements not only ensure safer chemical handling but also establish a significant strategic advantage that could well define the competitive landscape over the next decade.

Strategic Investments and Collaborations: Building a Resilient Future

Recent strategic investments in the packaging sector are indicative of a profound sense of urgency to adapt to global market shifts. Several major players have diversified their investment portfolios to include advanced R&D projects focused on durable, sensor-integrated drums, and containers. Such investments are key to managing the fine points of modern chemical packaging. Strategic collaborations are emerging between packaging companies and chemical manufacturers, with the shared goal of building internationally certified systems that can handle the most demanding applications.

In addition to R&D, companies are increasingly involved in developing circular-economy frameworks. These initiatives are not only about recycling and reusing materials— they are also about creating a comprehensive system where every part of the packaging lifecycle is considered. In doing so, companies are effectively reducing their environmental impact while ensuring that their products comply with the growing number of rules and regulations imposed by governments around the world.

The table below summarizes some of the key players and their strategic approaches in the evolving industrial chemical packaging market:

| Company | Key Focus | Strategic Approach |

|---|---|---|

| Greif Inc. | Recyclable IBCs & Sensor Tech | Heavy investment in R&D and global distribution efficiency. |

| Mauser Packaging Solutions | Sustainable Packaging Systems | Focusing on circular-economy models and compliance. |

| Berry Global Inc. | Advanced Polymer Materials | Integrating high-density plastics with monitoring sensors. |

| Sealed Air Corporation | Automated Safety Systems | Deploying real-time safety monitoring and leak detection technologies. |

| Sonoco Products Company | UN-Certified Containment Solutions | Diversifying their portfolio to include eco-friendly, reusable packaging. |

This snapshot of industry giants illustrates that the future of chemical packaging depends on continuous investments in technology, strong partnerships, and an unwavering commitment to both safety and environmental sustainability.

Opportunities and Challenges: Figuring a Path Through the Twists and Turns

No transformation comes without its share of intricate challenges. While the new approaches to industrial chemical packaging offer significant benefits, they are also accompanied by a set of challenging bits and confusing pieces that companies must figure out. The integration of advanced sensor technologies, novel materials, and automated systems can be overwhelming at times—especially for businesses transitioning from older systems.

Some of the key challenges include:

- High Initial Costs: Implementing smart, sensor-enabled packaging solutions often requires considerable upfront investment. Finding a path through these cost implications can be a nerve-racking process for smaller manufacturers.

- Regulatory Uncertainty: While regulations are tightening, keeping up with rapidly evolving rules in different regions can be tense and on edge. Businesses need flexible systems capable of adjusting to slight differences in each regulatory environment.

- Integration of Legacy Systems: Many established companies face the challenge of integrating new technologies with legacy systems. This process involves dealing with tangled issues and subtle parts that, if unresolved, could compromise overall efficiency.

- Supply Chain Adaptations: Changing the way chemicals are packaged has ripple effects throughout the supply chain. New logistics protocols must be developed, and staff may require specialized training to manage the next generation of packaging systems.

However, with every challenge comes an opportunity. Companies that can manage their way through these tricky parts not only stand to benefit from enhanced operational performance but also gain considerable strategic leverage. The key is to adopt a gradual, well-planned approach that allows for continuous learning and adaptation, rather than an abrupt leap into the new system.

Navigating the Digital and Physical Integration: A Dual Challenge

One of the more subtle aspects of this broader evolution is the integration of digital data management with physical packaging mechanisms. The digital footprint—a byproduct of initiatives such as cookie consent protocols—is becoming an integral part of how companies assess and fine-tune their packaging operations. Gaining control over both the digital data and the physical container performance creates a balance that is super important for long-term success.

This dual challenge requires businesses to be equally proficient at managing digital information and physical goods. For instance, while automated sensor systems transmit data in real time regarding container integrity and environmental conditions, the same data can be fed back into larger analytics systems to enhance operational planning and compliance monitoring. In essence, the line between digital transparency and physical efficiency is blurring, creating opportunities for synergistic improvements.

Adapting to this hybrid environment means not only investing in advanced packaging solutions but also establishing robust data processing and integrity measures. This is where the earlier discussion of digital consent practices takes on new meaning: just as businesses must allow customers to choose how their online data is tracked, they must also develop systems that prioritize data accuracy and security in monitoring packaging performance.

Consumer and Corporate Impacts: A Broader Perspective

The modernization of industrial chemical packaging has implications that extend far beyond the confines of the manufacturing floor. In an era where sustainability is a key driver of business decisions, consumers and regulators are increasingly scrutinizing how companies handle environmental waste and safety. This scrutiny is not just about meeting standards—it is about building trust and verifying that companies care about the planet.

For corporate executives, the decision to invest in advanced packaging serves as a declaration of commitment to both safety and sustainability. By aligning with the latest regulatory trends and adopting smart technologies, businesses can highlight their leadership in innovation. Moreover, improved packaging performance has the potential to enhance brand reputation, leading to better market positioning and long-term profitability.

On the consumer side, the move towards sustainable, automated packaging reinforces a growing demand for accountability in business practices. Whether it’s the safe containment of hazardous chemicals or the efficient recycling of industrial materials, every step taken towards smarter packaging is a step towards a greener, more secure future.

Working Through the Tangled Issues in Global Supply Chains

The ongoing transition in industrial chemical packaging also touches on the broader challenges faced by global supply chains. With cross-border trade on the rise, companies struggle with the tangled issues of regulatory harmonization and logistical coordination. Traditional packaging methods, once taken for granted, are being replaced with systems that must cater to increasingly varied and complex requirements.

As companies figure a path through these challenges, they must consider several factors:

- Compliance Verification: Ensuring that every container meets strict international standards is a super important part of the process.

- Logistic Flexibility: With a global market, the ability to adjust packaging to match diverse transportation requirements is a key competitive advantage.

- Cost-Benefit Analysis: Balancing the upfront costs of new technologies against longer-term savings and risk reduction remains a critical evaluation metric.

- Training and Adaptation: Workers need to get into the fine shades of how to handle these new systems, requiring significant changes in operational protocols.

Addressing these issues demands a well-coordinated strategy that pairs technological innovation with robust project management. Though the road ahead is loaded with issues, companies that make the effort now will be rewarded with a supply chain that is both agile and resilient in the face of future uncertainties.

Taking the Wheel: Leadership and Future Outlook in Chemical Packaging

Looking forward, the path ahead for industrial chemical packaging is framed by two key themes: sustainability and automation. These elements are not merely passing trends—they are foundational changes that will define the competitive environment for years to come. Companies that commit to integrating sensor-enabled devices, adopting sustainable materials, and streamlining their compliance processes will likely emerge as leaders in the field.

It is also evident that the investment landscape in the packaging sector remains vibrant. Strategic investments, ranging from joint ventures between packaging firms and chemical companies to government incentives for sustainable practices, have fortified the market’s growth trajectory. Such investments highlight an industry that is not afraid to take calculated risks and experiment with innovative solutions.

Senior executives must therefore steer through the following priorities as they plan for the future:

- Long-Term Environmental Goals: Deploying renewable and recyclable materials to meet not only current regulatory demands but also future environmental targets.

- Integration of Smart Technologies: Investing in sensor technology, IoT, and automated systems to boost operational resilience and safety.

- Cross-Industry Collaborations: Teaming up with chemical manufacturers, transportation firms, and tech developers to create end-to-end solutions that are both efficient and safe.

- Employee Training and Development: Ensuring that the workforce is educated in the latest technological processes, thereby smoothing the integration of new systems with legacy operations.

This strategic focus, combined with the willingness to experiment with new technologies, promises to usher in a new era where industrial chemical packaging is recognized as not only a necessity but also a strategic asset—one that contributes to a more sustainable global economy.

Conclusion: A Call for Transparency, Innovation, and Resilience

In conclusion, the transformation of industrial chemical packaging in Europe epitomizes the broader shift facing many industries today: the merging of digital transparency with physical innovation. From initial data consent issues related to online operations, through the fine points of sustainable material integration and sensor-enabled monitoring, every facet of modern chemical packaging is being redefined.

Companies and regulators alike face the complicated pieces and intimidating challenges of today’s rapidly changing environment. Yet, the compelling opportunities—ranging from enhanced safety protocols to significant environmental benefits—make the journey worthwhile. By investing in advanced research, forging strategic partnerships, and maintaining a keen eye on both business and environmental trends, industry leaders can overcome the nerve-wracking twists and turns that lie ahead.

As you figure a path through the digital and physical landscapes of modern business, remember that every step taken towards improved packaging is a positive move towards better compliance, increased safety, and a healthier planet. Whether you are a seasoned executive or a newcomer to the field, it is clear that sustainable and smart industrial chemical packaging is not just a fleeting trend—but an essential evolution shaping the future of global business.

This editorial invites all stakeholders to dive in, take a closer look at the emerging trends, and embrace the integration of smart technology with sustainable practices. The road ahead may be full of challenging bits and minor twists, but by working together and keeping an open mind, the industry can successfully manage its way through these changes, emerging stronger, safer, and more responsible than ever before.

In an interconnected world where digital privacy, rigorous data consent, and cutting-edge manufacturing intersect, the industrial chemical packaging market serves as a prime example of how innovation can overcome tensions and create opportunities for growth. With its deep commitment to environmental stewardship and operational excellence, the chemical packaging sector is poised to drive lasting change both within Europe and on the global stage.

Ultimately, the transformation we are witnessing today is a vivid reminder that progress often comes hand in hand with challenges. As companies continue to orchestrate their strategies and navigate through the tricky parts of design, technology integration, and regulatory compliance, the future holds immense promise for a safer and more sustainable industrial era.

Let us embrace this journey, leveraging both practicality and creativity to ensure that our approach to industrial chemical packaging not only meets current needs but also lays a solid foundation for a more innovative and responsible tomorrow.

Originally Post From https://www.openpr.com/news/4275737/industrial-chemical-packaging-top-europe-industry-trends

Read more about this topic at

Smart sustainable plastic packaging

Packaging innovation – Amazon Sustainability