Understanding the Nylon Acid Dye Fixing Agent Market

The current landscape of the nylon acid dye fixing agent market reflects a fascinating blend of technological innovation, evolving regulatory standards, and dynamic customer demands. In this opinion editorial, we take a closer look at what is driving growth, production technology shifts, and automated systems—even as textile manufacturers manage their way around various tricky parts and tangled issues.

Market Growth Trends and Outlook

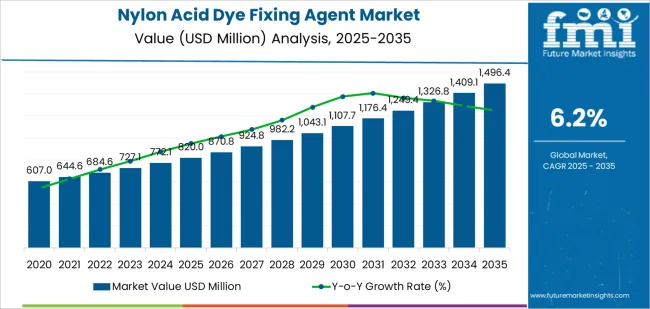

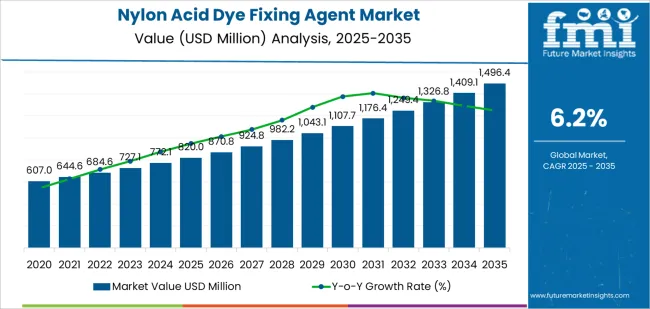

The nylon acid dye fixing agent market is projected to expand commendably from USD 820 million in 2025 to about USD 1,496.4 million by 2035. With a compound annual growth rate of approximately 6.2%, this market is not only poised to add significant absolute value but also to experience an overall growth of 82.5% over the next decade.

This optimistic forecast is driven largely by:

- Expansion in global textile manufacturing

- Increasing quality standards in nylon dyeing

- The adoption of advanced fixation technologies across the fashion and industrial sectors

These trends underline the critical requirement for chemical solutions that can handle high-temperature, chemically intensive processing—a demand that is steadily pushing the boundaries of chemical formulations in the textile industry.

Technological Innovations in Chemical Formulations

Advanced Formulation Technologies in Textile Manufacturing

In the world of textile finishing, even the tiny details matter. Manufacturers are now investing in chemical engineering processes that go beyond the basic performance of traditional acid dye fixing agents. Significant attention is given to:

- Reactive polymeric fixatives that deliver superior color retention

- Eco-friendly formulations that meet emerging environmental guidelines

- Integrated chemical control systems aimed at enhancing both production efficiency and compliance

The shift toward advanced chemical synthesis and automated dosing systems is not without its tricky parts and confusing bits. However, these innovations ensure precise control over dye fixation processes, which translates into improved wash durability and consistent performance under challenging processing conditions.

Automation Systems and Dosing Precision

Automated systems are playing a crucial role in the modernization of textile production. Through digital processing and smart manufacturing, textile manufacturers now have the tools to get into the nitty-gritty of quality control. Automated dosing systems offer higher precision when applying fixatives, thereby reducing waste, minimizing operator error, and ultimately increasing production efficiency.

Some highlights of these systems include:

- Real-time monitoring of application rates

- Integration with existing textile processing machinery

- Data tracking for continuous performance improvement

Overall, the emergence of these technologies is steering the industry toward more efficient and sustainable production models—a real game changer in terms of reducing both operational costs and environmental impact.

Application Trends: From Clothing to Industrial Nylon

Diverse Applications Across Textile Segments

Acid dye fixing agents originally found their niche in clothing applications, where the need for vibrant, long-lasting color retention is paramount. Today, these chemicals have permeated a wide range of textiles, from home textiles to industrial nylon and even automotive textiles.

Key application highlights include:

- Clothing: Representing nearly half of the current market share, clothing applications continue to expand driven by the fast-changing fashion industry.

- Home Textiles: Demand grows steadily as manufacturers upgrade processes to meet stringent quality guidelines.

- Industrial Nylon: Specialized industrial applications requiring high technical performance also contribute to the growth of the market.

- Automotive and Technical Textiles: Emerging segments illustrate how advanced fixation technology can be tailored to meet specialized industrial requirements.

These segments, along with innovations in chemical formulations, reflect subtle shifts and small distinctions between market administrators and end-users. Such variations require companies to find your way through increasingly complicated pieces when meeting operational demands.

Comparative Insights on Method Segments

Methodology in the application of acid dye fixing agents is an essential area where several approaches compete for prominence. Among these, the dipping method currently dominates with a 58.4% market share. This technique is especially favored in large-scale fabric processing operations.

Other notable methods include:

- Padding Method: Offers continuous textile processing capabilities and is ideal for modern automated systems.

- Spray Application Method: Although technically more complex than the dipping method, it is advancing slowly due to the targeted precision it offers.

- Exhaust Method and Others: These specialty methods cater to niche requirements and continue to gain traction in selected textile processing facilities.

Each method comes with its own set of twists and turns, requiring manufacturers to examine both technical performance and cost-effectiveness before adopting a particular process.

Regional Market Dynamics and Expansion Strategies

Regional Growth Prospects and Government Support

The geographical distribution of market growth underscores significant national and regional factors. For example, burgeoning textile hubs in Asia-Pacific, Europe, and North America are each contributing to the steady expansion of this market. Specific trends include:

- China and India are witnessing remarkable growth rates of 8.4% and 7.8% respectively, driven by extensive automation upgrades and infrastructure projects.

- Germany and Brazil follow closely, benefiting from engineering excellence and modernized processing capabilities.

- Regions such as the United States, United Kingdom, and Japan maintain growth through technological innovation and the integration of precision dyeing systems.

These regional dynamics illustrate how government-backed initiatives and industrial modernization programs are essential in pushing the market forward. Although the regulatory environment can sometimes be intimidating and filled with tricky parts, these efforts ultimately lead to robust market confidence and improved safety standards.

Case Studies in Regional Market Expansion

A closer look at regional market patterns reveals the following illustrative examples:

| Country | Forecast CAGR (2025-2035) | Key Focus |

|---|---|---|

| China | 8.4% | Industrial automation, digital textile systems |

| India | 7.8% | Textile manufacturing modernization, infrastructure upgrades |

| Germany | 7.1% | Engineering precision, advanced automation capabilities |

| Brazil | 6.5% | Modernized processing, industrial infrastructure development |

| United States | 5.9% | Technological innovation, precision dyeing systems |

| United Kingdom | 5.3% | Legacy system upgrades, innovation in chemical fixing |

| Japan | 4.7% | Export-oriented component production, textile technology tradition |

Such regional case studies clearly show that while the market is loaded with challenges and occasional confusing bits, strategic government projects and industrial modernization help manufacturers figure a path forward.

Environmental and Regulatory Influences

Strengthening Environmental Standards and Safety Protocols

With growing concerns over environmental protection and worker safety, the textile industry is increasingly pressed to adopt eco-friendly solutions that minimize waste while maintaining high performance. Key regulatory drivers include:

- Enhanced safety standards for chemical usage

- Strict environmental guidelines that mandate reduced chemical waste

- Certification and testing protocols to guarantee consistent performance

While these regulations may appear a bit intimidating and produce off-putting documentation procedures, they are essential in ensuring that textile processes remain within the bounds of safety and quality standards. The industry’s move toward eco-friendly formulations and integrated chemical control systems represents a must-have shift in today’s sustainable manufacturing environment.

Compliance Requirements and Quality Assurance Systems

The regulatory landscape for nylon acid dye fixing agents is full of problems and riddled with tension when it comes to maintaining consistent quality across international markets. Manufacturers are increasingly investing in comprehensive quality assurance systems and validation procedures within their supply chains.

Some key compliance actions include:

- Development and adherence to international textile quality standards

- Regular audits and inspections to ensure regulatory compliance

- Certifications that verify chemical performance and worker safety

These measures enable both suppliers and textile manufacturers to work through the confusing bits of compliance while maintaining the delicate balance between performance, cost-effectiveness, and environmental conservatism.

Investment and Competitive Landscape

Market Leaders and Competitive Strategies

In a sector where competition is stiff and the twists and turns of technological innovation continue to reshape the market, several companies have established themselves as frontrunners. Leading players such as Dow, Senka Thailand, and CHT Group are not just selling chemicals—they are offering integrated solutions that combine advanced formulation, process automation, and regulatory assurance.

What sets these market leaders apart is their ability to:

- Maintain extensive portfolios in chemical synthesis and textile finishing

- Invest heavily in research and development to fine-tune product performance

- Establish strong, long-term relationships with major textile manufacturers

These companies are often seen integrating digital processing and automated dosing systems into their product warranties, thereby making their products essential for modern textile operations. Although the market is occasionally filled with nerve-racking operational challenges, these established players are well positioned to manage their way through the tricky parts and confusing bits surrounding market demand and supply chain integration.

Economic drivers and Competitive Edge

Investors seeking opportunities in the nylon acid dye fixing agent market must consider several key factors:

- Rising production costs – pushing companies to adopt more automated methods and precision dosing systems

- Demand for high-performance chemicals – driven by more rigorous consumer quality requirements and industrial safety norms

- Growth in adjacent markets – such as advanced textile processing systems that require both quality assurance and operational efficiency

The competitive landscape is evolving as companies increasingly focus on value-added services rather than merely producing basic chemical components. This shift toward integrated, application-ready solutions not only provides a competitive edge but also plays a key role in shifting the overall market dynamics. Despite these nerve-racking adjustments, it remains clear that companies which are willing to dig into the nitty-gritty of research and innovation will be the ones to watch in the coming years.

Opportunities and Challenges Ahead

The Promise of Technological Integration

Innovation in the nylon acid dye fixing agent market is not solely a function of chemical synthesis; it extends further into process optimization and system integration. As companies adopt streamlined chemical control systems within automated textile processing lines, several promising trends become evident:

- Integration of smart manufacturing for real-time data feedback

- Enhanced process control for improved consistency in production

- Collaborations between textile manufacturers and chemical suppliers to craft tailored solutions

These advances are critical in ensuring that production systems can cope with both the subtle parts of quality assurance and the challenging demands of industrial scale manufacturing. It is now more essential than ever for companies to find their way through complicated pieces of technology integration and to take advantage of the flexible, adaptive systems emerging in the market.

Overcoming Production and Operational Hurdles

Despite the impressive market growth and technological progress, several operational challenges persist. Textile manufacturers and chemical suppliers often face:

- Tricky parts in integrating new automated dosing systems into legacy production lines

- Tangled issues surrounding the calibration of advanced chemical formulations

- Confusing bits in balancing production efficiency with strict regulatory adherence

Addressing these matters requires a multifaceted approach. Companies must invest in training, upgrade their equipment, and collaborate closely with regulatory bodies to ensure that environmental and safety standards are met. While the path forward is not always straightforward, the industry’s willingness to adapt and innovate signals promising prospects for overcoming these obstacles.

Strategies for Manufacturers and Supply Chain Stakeholders

Adopting Integrated Processing and Automated Systems

For businesses looking to capitalize on this market, a key recommendation is to invest in integrated processing solutions. This means combining advanced chemical formulations with robust, automated application technologies. The benefits of these integrated systems include:

- Enhanced precision in chemical dosing

- Streamlined production cycles

- Greater consistency in product quality and performance

These improvements not only boost operational efficiency but also help manufacturers steer through the complicated pieces of modern textile finishing. It remains essential to leverage both new innovations and reliable legacy practices to create a balanced, efficient production system.

Collaborative Partnerships and R&D Investments

Another avenue for progress involves forging strong partnerships between textile companies, chemical suppliers, and technology providers. Collaboration allows stakeholders to:

- Share insights and best practices on process automation

- Develop bespoke solutions that address specific industrial needs

- Accelerate research and development initiatives to tackle emerging challenges

These alliances are particularly valuable when it comes to managing the small distinctions between production methods and regulatory requirements. By working together, firms can more easily find their way through the overwhelming landscape of new technology and industry compliance.

Looking Forward: The Future of Textile Processing

Impact on Fashion, Home Textiles, and Industrial Applications

As the nylon acid dye fixing agent market continues to mature, its impact will extend far beyond conventional textile applications. From the vibrant colors of fashion garments to the enduring quality of home textiles and the demanding performance needs of industrial nylon components, advanced chemical solutions are set to become a cornerstone of textile processing.

Looking ahead, we expect to see:

- Greater customization in chemical formulations to meet specific performance needs

- Ongoing evolution in automated processing systems that offer both efficiency and precise control

- Deepening integration of digital monitoring systems for tighter quality assurance and cost control

These developments signal a future in which the textile industry becomes more resilient, sustainable, and responsive to an ever-changing marketplace. Even as rough patches and nerve-racking challenges emerge, the overall trajectory remains positive—a testament to the resilience and innovation of the industry.

Strategic Recommendations for Industry Stakeholders

For business leaders and industry stakeholders, several strategic recommendations can help mitigate the tricky parts and intricate twists that define this sector:

- Invest in cutting-edge automated systems: Embrace technological advancements to boost efficiency and reduce human error.

- Focus on eco-friendly solutions: Align with environmental regulations by prioritizing sustainable chemical formulations and production methods.

- Strengthen quality assurance protocols: Develop robust compliance and testing procedures that ensure consistent product performance.

- Cultivate collaborative networks: Partner with technology providers and regulatory bodies to stay ahead of emerging market trends and operational challenges.

- Prioritize R&D: Dedicate resources to innovation and product development, ensuring the capacity to respond to small distinctions in market demand and consumer expectations.

Final Thoughts: Balancing Innovation with Practicality

The nylon acid dye fixing agent market is a compelling example of how technological integration, regional investments, and strategic innovation can transform an entire industry. While there remain several confusing bits and nerve-racking challenges, stakeholders are increasingly finding creative ways to manage their way through production hurdles and regulatory twists and turns.

In the end, the industry’s evolution will depend on the ability of major players and emerging competitors alike to balance innovation with practicality. By taking a closer look at advanced formulation technologies, automated processing systems, and collaborative R&D efforts, businesses can pave the way for more efficient, sustainable, and high-quality textile production.

Ultimately, as textile manufacturers continue to adopt and refine these advanced chemical solutions, they not only enhance product performance but also contribute to a more dynamic, resilient, and forward-looking industry—one that is well-prepared to embrace the challenges and opportunities of tomorrow.

Summary and Key Takeaways

To sum up, here are the principal observations from our analysis:

- The market is projected to grow by 82.5% from 2025 to 2035, driven by increased textile manufacturing and advanced fixation technologies.

- Technological innovations in chemical formulations and automation systems are revolutionizing production efficiency and quality control.

- Diverse application segments—from clothing to industrial nylon—create multiple avenues for market expansion, each with its own set of small distinctions and technical challenges.

- Regional market growth is strongly influenced by government-backed infrastructure upgrades and modernized processing capabilities, especially in Asia-Pacific, Europe, and North America.

- Environmental and regulatory pressures are prompting the adoption of eco-friendly, sustainable chemical solutions, despite the nerve-racking issues involved with stringent compliance.

- Collaboration between industry stakeholders, ongoing R&D investments, and strategic partnerships are imperative to managing the tricky parts of technological and operational integration.

With these insights in mind, industry leaders can not only appreciate the current opportunities but also better prepare for a future that promises both challenges and exciting breakthroughs in textile processing and chemical innovations.

Conclusion: A Path Forward

Ultimately, the nylon acid dye fixing agent market offers a fascinating glimpse into how technological progress, environmental sustainability, and strategic industry collaboration come together to enrich the textile manufacturing landscape. By embracing advanced formulations, automated systems, and integrated quality assurance protocols, companies are poised to meet the ever-evolving demands of a global marketplace.

Even though there are several tangled issues and confusing bits along the way, the overall direction of the market is upbeat. With proactive strategies and a focus on innovation, the textile industry is set to not only sustain but also thrive in the years ahead—proving that with the right approach, even the most overwhelming challenges can be transformed into critical drivers of success.

Originally Post From https://www.futuremarketinsights.com/reports/nylon-acid-dye-fixing-agent-market

Read more about this topic at

Dye Fixation → Term

Pre-Treatment & Dyeing – SNF